In addition to the upcoming battery manufacturing facility, multiple UT research labs have capabilities to produce and test full-cell batteries with capacities up to 200 mAh. Commercially relevant electrode mass loadings and cycling protocols are employed along with detailed cell performance and electrochemical property assessment.

Standard Cell Prototype Capabilities

- Centrifugal, High-Shear and Ultrasonic Mixers/Processors

- Temperature-controlled Coaters

- Hot Rolling Presses and Vacuum Ovens

- Automated Electrode Punchers

- Coin Cell and Single-Layer Pouch Cells (up to 200 mAh)

- Gloveboxes

- Crimpers

Cell Performance Evaluation

- Over 1,500 battery cycler channels with various current ranges up to 30A

- Specialized cells for advanced evaluation

- Three-electrode cells for inclusion of a reference electrode

- Optical cells for in operando visual analysis during charge/discharge, e.g. probing dendrite formation or lithium plating

- Electrochemical Impedance Spectroscopy (EIS)

- Environmental Chambers for controlled temperature evaluation at temperature extremes

Faculty in This Area

Michael Aubrey

John Goodenough

Hadi Khani

Brian Korgel

Arumugam Manthiram

David Mitlin

Buddie Mullins

Venkat Subramanian

Guihua Yu

Recent Research Projects

Crossover Effects in Cells with High-nickel Layered Oxide Cathodes and Silicon/Graphite Composite Anodes

Arumugam Manthiram

Advanced Energy Materials

Lithium Trapping in Germanium Nanopores during Delithiation Process

Buddie Mullins

Applied Materials Today

Analysis of Early Failure of Lithium–Sulfur Batteries: Crosstalk between Sulfur Cathode and Lithium Anode

Venkat Subramanian

Advanced Science

Dimensionality Effect of Conductive Carbon Fillers in Cathodes

Guihua Yu

Carbon

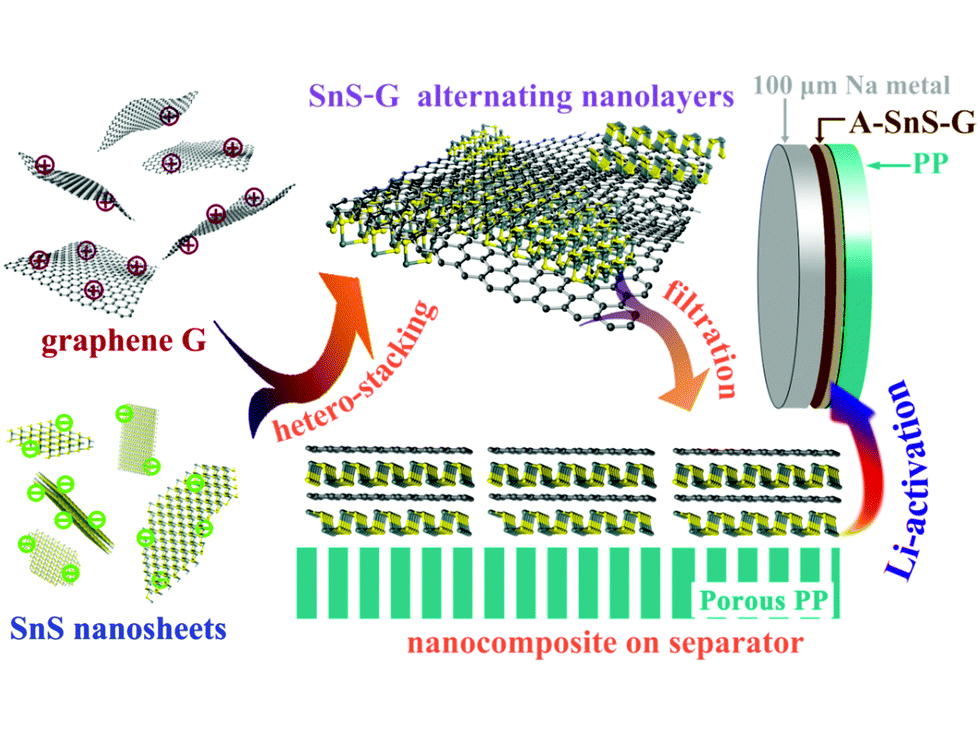

Dendrite-free Cycling of Thin Na-metal Anodes

David Mitlin

Energy and Environmental Science

An Optimized Li-S Cell

John Goodenough

Advanced Functional Materials